DDS2030Fully Automatic Die Separator

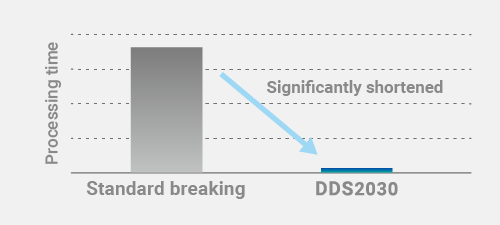

A die separator that significantly shortens the breaking time

- Φ300 mm

- SDTT

Achieves high productivity regardless of die size

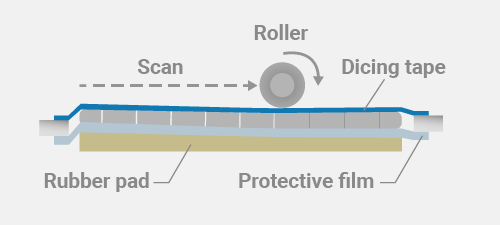

DDS2030 achieves high-throughput separation of wafers where a modified layer has been created inside the wafer using the Stealth Dicing™ process. Unlike the existing method, which requires breaking each line individually, DDS2030 uses a roller-scanning method to separate ultra-small die that cannot be singulated by tape expansion alone, realizing both high productivity and high quality.

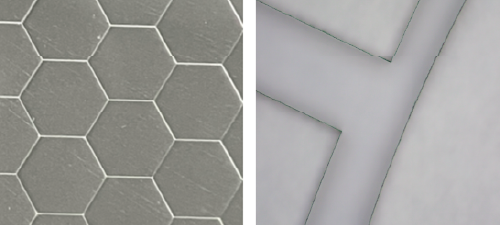

Separation of various shapes including polygonal die and along curved lines

Separation is possible even for non-linear processing lines, including polygonal die and curved shapes.

Automatic mounting and peeling of protective film

As a surface protective film mounting and peeling mechanism is built into the equipment, the entire series of processes, from film mounting, through breaking, to peeling, can be carried out within the equipment.

Specifications

| Specifications | Unit | DDS2030 |

|---|---|---|

| Supported tape frame size | mm | Specification compatible with both Φ300 and Φ200 Note: Size conversion operation is required to switch the tape frame size |

| Equipment dimensions (W×D×H) | mm | 1,550 × 1,900 × 1,800 (excluding status light) |

| Equipment weight | kg | Approx. 1,600 |

* Please read the standard specification sheet before using the equipment.

* Please note that items and specifications may be changed for improvement without prior notice.

Product Lineup

DDS2030Fully Automatic Die Separator

Contact

Please feel free to contact us with any questions or inquiries.