DGP8762Fully Automatic Grinder/Polisher

A grinder/polisher for Φ300 mm workpieces that achieves improved processing accuracy and throughput

- Φ300 mm

- 3 axes, 4 chuck tables

- DBG

- SDBG

- Wafer Thinning

- Stress Releaf

Next-generation grinder/polisher that supports Φ300 mm wafers

DGP8762 integrates the processes from backgrinding to stress relief, and is a grinder/polisher for wafer thinning and the successor to DGP8761. By optimizing the processing point through methods such as adding a cooling mechanism, high accuracy and throughput can be achieved. In addition, due to automation of dressing performed after wheel replacement, it is possible to reduce operator work.

Supports difficult-to-process materials

By installing a high-torque spindle (optional specification), DGP8762 can support thinning of difficult-to-process materials including SiC. Additionally, by adding a load detection function (optional specification), it is possible to prevent wafer breakage caused by wheel push-in.

Various Z3 spindle configurations

The following Z3 spindle configurations for thin wafer processing can be selected:

Dry polishing (standard)

an environmentally-friendly polishing process that does not use chemicals or water

CMP (optional)

a polishing process where polishing is performed using chemicals and water by mounting a CMP pad instead of the dry polishing pad

Grinding (optional)

a polishing process that improves the productivity by performing grinding on all 3 axes by mounting a grinding wheel instead of the dry polishing pad

Can be used as part of MUSUBI

DGP8762 is compatible with MUSUBI, a cluster system that connects multiple equipment units. MUSUBI enables selection of an equipment combination that is suitable for the customer’s manufacturing process. As transfer within the equipment is automated, it is possible to achieve wafer breakage risk reduction and improved throughput.

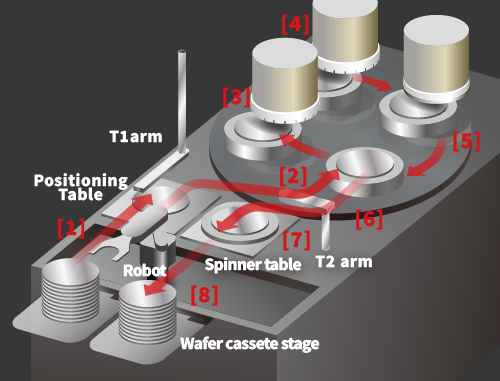

Workflow

- The robot pick unloads a workpiece from the cassette and places it on the positioning table, where centering takes place.

- The T1 arm places the workpiece on the chuck table.

- The workpiece proceeds to Z1 for rough grinding.

- The workpiece proceeds to Z2 for fine grinding.

- The workpiece proceeds to Z3 for dry polishing (stress relief).

- The T2 arm unloads the workpiece from the chuck table and places it on the spinner table.

- Cleaning and drying

- The robot pick returns the workpiece to cassette.

Specifications

| Specification | Unit | DGP8762 | |

|---|---|---|---|

| Supported workpiece size | mm | Φ200, 300 | |

| Processing method (Z1/Z2 axis) | - | In-feed grinding with workpiece rotation | |

| Processing method (Z3 axis) | - | Dry polishing/CMP: in-feed grinding with workpiece rotation Grinding: anomalous in-feed grinding with workpiece rotation |

|

| Wheel / pad used | - | Φ300 mm diamond wheel (grinding axis) Φ450 mm dry polishing pad (dry polishing axis) Φ450 mm CMP pad (CMP axis) |

|

| Equipment dimensions(W × D × H) | mm | 1,690 × 3,451 × 1,800 | |

| Equipment weight | kg | Approx.6,850 | |

*Please read the standard specification sheet before using the equipment.

*Please note that items and specifications may be changed for improvement without prior notice.

Product Lineup

| Machine type |

| Spindle |

| C/T |

| Machine dimentions(W × D × H) |

| Machine weight(kg) |

DGP8762Fully Automatic Grinder/Polisher

Contact

Please feel free to contact us with any questions or inquiries.