Development of Three Types of New Dicing Blades and New Dry Polishing Wheel

DISCO CORPORATION, a semiconductor manufacturing equipment manufacturer (Head Office: Ota-ku, Tokyo; President: Kazuma Sekiya), has newly developed the following dicing blades: ZHSR Series, TM22 Series, and BH23 Series, and the following dry polishing wheel: DPEG Series SZ Type for the semiconductor and electronic components market.

These products will be exhibited at SEMICON Japan 2023 (December 13–15, Tokyo Big Site).

ZHSR Series: Hub Blade for Silicon Wafer Dicing

Background:

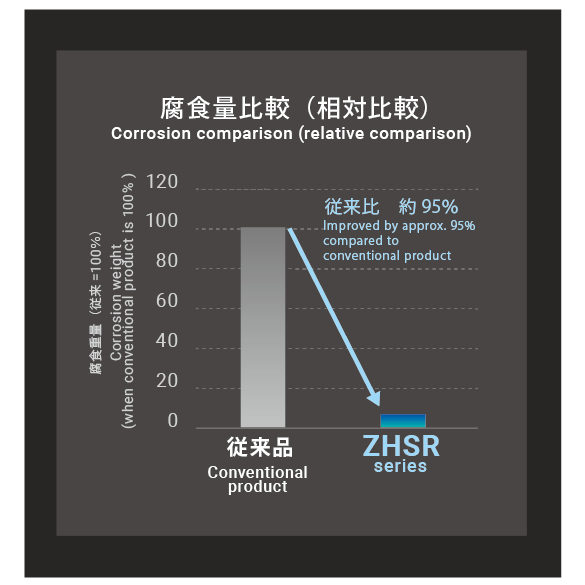

With the recent progress in miniaturization within the semiconductor manufacturing process (e.g., logic memory), thorough countermeasures against static electricity are required. Highly pure water is used as a coolant and for cleaning during the wafer dicing process, but since highly pure water is nonconductive, a common countermeasure is to dissolve CO2 to provide conductivity. However, if the concentration of CO2 in the highly pure water is increased to suppress the amount of static electricity, corrosion will occur in electroformed blades.The ZHSR Series has achieved improved corrosion resistance while maintaining high processing quality.

Features:

- Newly developed bond material

- Significantly improved corrosion resistance

- Improves yield by reducing wavy cutting and breakage due to blade tapering

- Promotes self sharpening and achieves high-quality processing

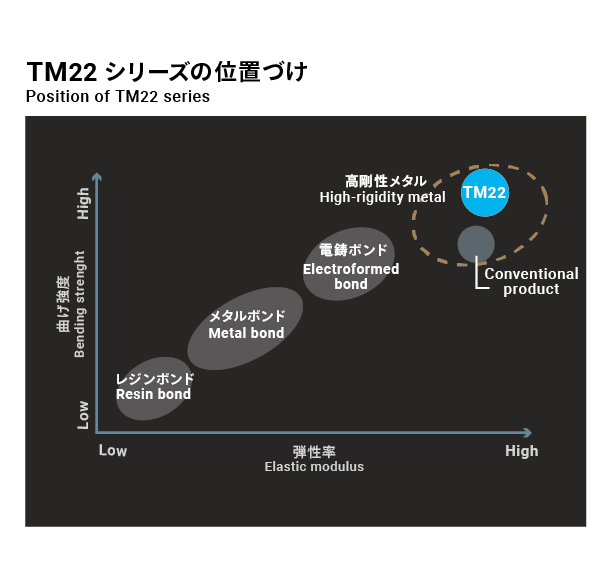

TM22 Series: High-Rigidity Metal Bond Blade

Background:

For passive components, such as condensers, die shape and volume after dicing affect product performance. Therefore, high dimensional accuracy is required from processing. As a successor to the TM11 Series, the TM22 Series can achieve high-precision processing with its increased bond strength and can contribute to improved productivity.

Features:

- Newly developed bond with increased strength

- Improves die dimensional accuracy after processing

- Improves yield by reducing wavy cutting and breakage due to blade tapering

BH23 Series: Metal/Resin Bond Blade Compatible with ABC (Automatic Blade Changer)

Background:

ABC is a function that automatically replaces hub blades during silicon wafer dicing. This function is recognized for its contributions in preventing operator error and improving operation rate. This automation is currently also in demand for metal/resin bond blades used to dice electronic components and packaging. With an aluminum hub bonded to its metal/resin blades, the BH23 Series is compatible with ABC, thus promoting automation.

Features:

- Supports metal, resin, and other bonds

- Individual blade information engraved to hub as 2D code

- Automatically sends actual measurement values for blade exposure and thickness to equipment

- Prevents human error such as blade mounting errors and/or value input errors

- Automatically records serial number of blades used, ensuring traceability

- Reduces downtime caused by wait for operator to start operation

- Improves equipment operation rate

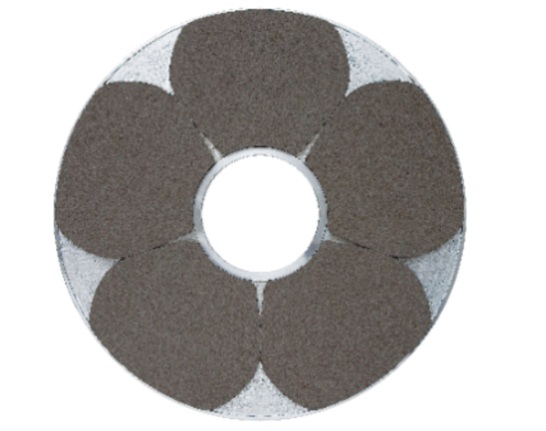

DPEG Series SZ Type: Gettering DP Wheel for Silicon Wafers

Background:

In order to increase the strength of the wafer in silicon wafer thinning, undulations on the grinding surface need to be removed. However, if undulations are completely removed, the gettering effect* is lost, leading to wafer property errors due to heavy metal contamination. The DPEG Series SZ Type has been newly added to the gettering DP wheel lineup for solving this issue. The DPEG Series SZ Type can achieve higher die strength than the conventional product while maintaining the gettering effect.

*The gettering effect is a mechanism that forms crystal defects or distortions (= gettering sites) inside the silicon wafer or on the backside and then captures impurities that cause heavy metal contamination within these gettering sites. Gettering DP wheels form gettering sites by making minute scratches on the wafer backside, which then capture these heavy metal impurities.

Features:

- Improved pad composition

- Improves die strength by approx. 1.3 times while maintaining gettering effect (when compared with conventional product)

Schedule

All four products are available for purchase. Please contact a DISCO sales representatives for details.

About DISCO

DISCO is a semiconductor equipment manufacturer that provides precision processing equipment, including dicing saws and grinders, and precision processing tools (blades and wheels) used for manufacturing semiconductors and electronic components. In addition to these products, as a result of pursuing optimal processing results for customers through the provision of the technology used with the equipment and tools, DISCO products and processing technologies have been widely adopted by device manufacturers and semiconductor subcontractors both domestically and internationally. For details, please visit the DISCO website at www.disco.co.jp.

Contact

Please feel free to contact us with any questions or inquiries.